When building a new data centre near Vienna, ACO was consulted as a partner for managing the surface water. What nobody knew at the beginning was that this would become ACO Austria's biggest project of all time.

ACO was originally contacted by those responsible for the supply of mineral oil separators. Due to the scope of the request, it was quickly recognized internally that this would be a complex and large project. The team then offered the client a presentation on the advantages of ACO’s entire system chain. The many advantages of technical filters, Stormbrixx and the GRP material, were of great importance so after much discussions the client accepted ACO’s offer.

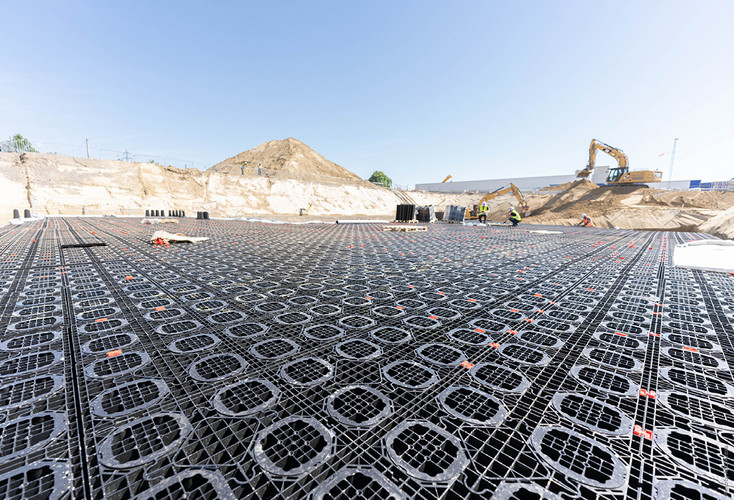

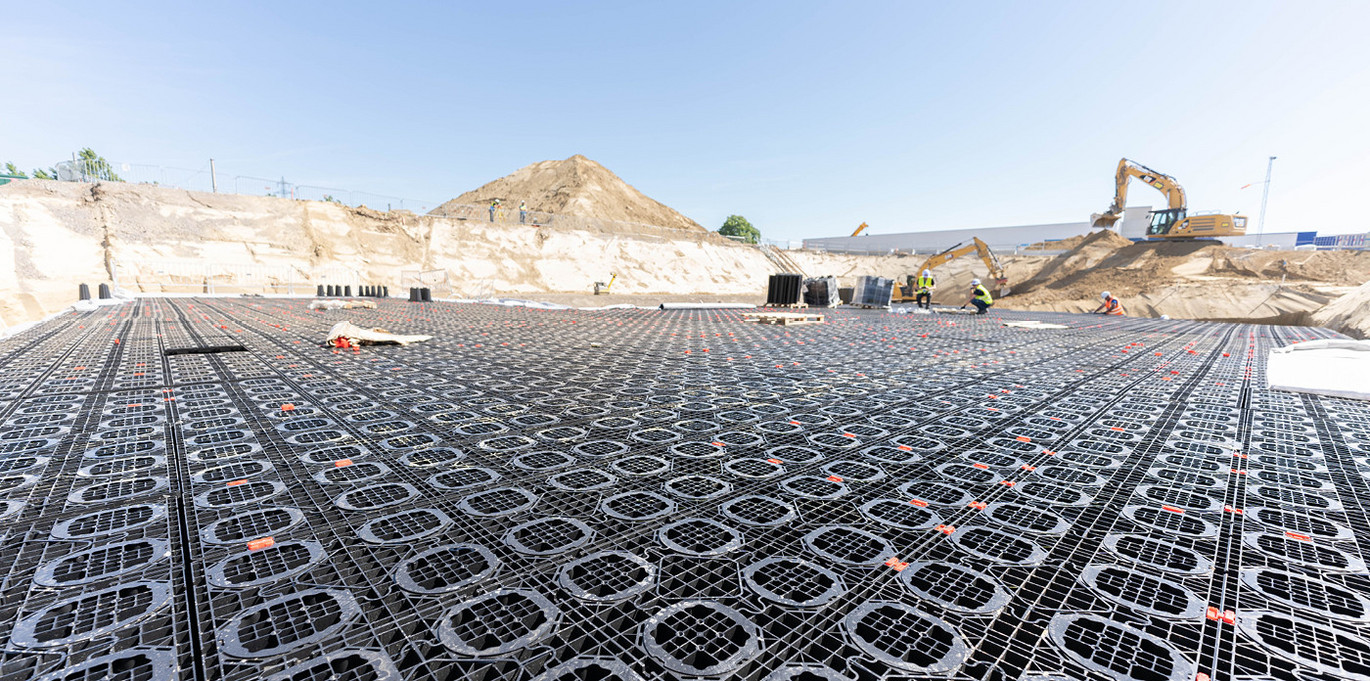

The task facing them was a huge area of almost 40,000 square meters which would need to withstand a 1 in 100-year rainfall event, while performing perfectly every day.

The product volume required as well as delivery from various corners of ACO’s supply chain were enormous. However, by becoming a single point of contact, ACO managed to arrange the entire system chain for delivery on time and as scheduled.

Due to the size of this project, ACO's high quality service also came to the fore. 5 people from the office in Baden were at hand to answer any questions from the construction team. Furthermore the site was visited more than 10 times in order to provide the client and contractors with the best possible support.

As the result ACO system took 2’000m3 of gravel off installation, halved the planned excavation required thus vastly reducing labour and mock away cost and finally off-site installation and preparation of products further reduced installation time & costs.