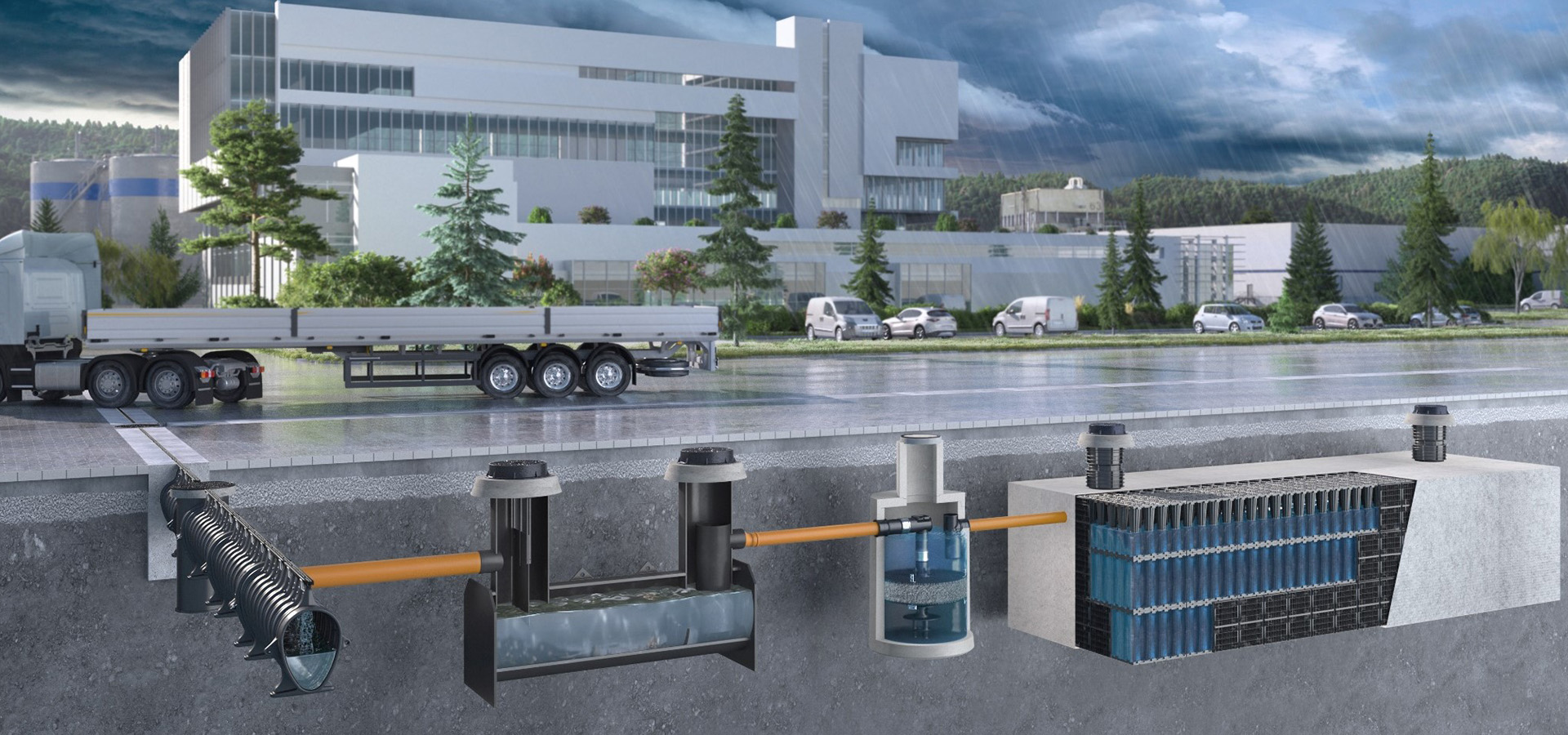

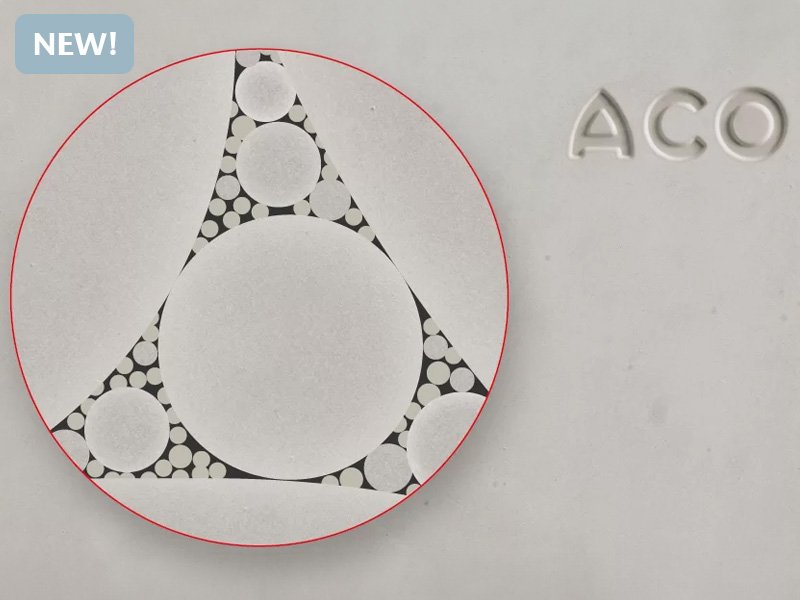

Polymer-concrete

Polymer concrete offers exceptional mechanical properties, chemical resistance, and durability. By replacing traditional binders with polymers, it enhances strength, reduces permeability, and extends lifespan. Its versatility, reduced maintenance, and sustainability make it an ideal choice for infrastructure, industrial, and architectural applications.